[ad_1]

A robotic arm gets to work at German manufacturer Rittal’s smart factory in Haiger, to the west of Hesse, Germany.

Rittal

Conversational artificial intelligence that can be used to communicate with equipment and generate machine parts. Digital versions of vehicles and planes that can be modified to fine-tune their physical counterparts. And autonomous robots that move as you walk by.

These are just a few of the technologies that will power the factories of the future, according to technologists and industry experts who spoke with CNBC.

In the future, factories will be much more connected, relying on a mix of technologies, from artificial intelligence, data platforms and edge devices to the cloud, robotics and sensors, Goetz Erhardt, Europe lead for Accenture’s digital engineering and manufacturing division, told CNBC.

“These technologies support fully automated, ‘dark’ plants, automated decision-making, enhanced equipment monitoring, and new production networks with recycling and upcycling capabilities,” Erhardt said via email.

Today’s factories — from those used in machinery and automobiles to food processing plants — have progressively become more advanced with regard to adopting technology. Robotic arms involved in the manufacturing process — adding and removing materials, welding and placing goods on pallets — are now a common sight.

More advanced A.I.

As much more advanced artificial intelligence technologies are added into the mix, the industrial manufacturing process could shake up further. Conversational systems such as OpenAI’s GPT could one day become integrated into robotics, enabling more sophisticated, emotionally intelligent machines.

Google is among the tech world giants looking to capitalize on large language models, which can generate more humanlike responses thanks to the huge amounts of data they are trained on. The company launched its own AI chatbot Bard earlier this year to rival OpenAI’s ChatGPT.

Consumer products aren’t the only focus of Google’s AI efforts. The company recently upgraded its cloud platform for manufacturers to more efficiently pull data from machines and detect anomalies in the production process.

Going forward, AI will be able to “converse using natural language with manufacturing equipment to understand the current state and the predicted future performance — therefore assisting people and allowing them to focus on high value tasks,” Google Cloud’s Floyd told CNBC.

Floyd said that Google is already working to achieve this with natural language processing capabilities in its AI tools. The company has also created a language model for robots called PaLM-E, which gathers sensory information from the physical environment, as well as text-based inputs.

Engineers will eventually be able to develop new machinery using generative AI tools, Floyd said.

“In the future, there is potential to generate content from and for many types of manufacturing equipment, ranging from specific repair instructions to software code that is tailored to a specific asset.”

‘Digital twins’

One development many industrialists are excited about is “digital twins” — 3D digital replicas of objects in the physical world that can be modified and updated in parallel with the items they aim to mimic.

One example of a company using digital twins to aid its physical manufacturing is Rolls Royce, whose engineers create precise virtual copies of its jet engines and then install sensors and satellite networks on-board to feed back data to the digital copy in real time.

“For every modern Rolls Royce jet engine up on a plane in the sky, there’s one in the cyber sphere that needs to be maintained, working out how much stress is going through the plane,” said John Hill, CEO of Silico AI, a startup that focuses on digital twins for business processes. “That will depend on how the engine is faring in the atmospheric conditions and pressures in the air.”

Another example is Renault, which created a digital twin for a new “software-defined” car with artificial intelligence capabilities to enhance services.

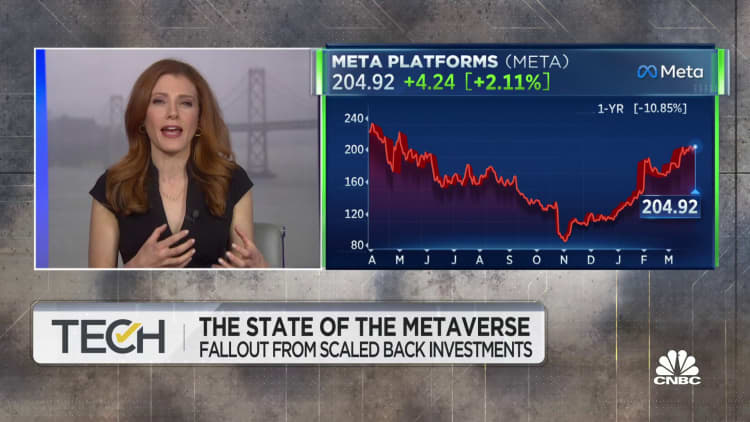

Digital twins form part of the so-called “metaverse,” which embodies the idea that people will spend more of their work and leisure time in huge 3D digital spaces. Some companies are also looking to incorporate the physical world in some iterations of the metaverse.

Many manufacturers see potential in the “industrial metaverse,” a version of the metaverse tailored to the manufacturing, construction and engineering industries. Accenture’s Erhardt told CNBC that he is mainly seeing use cases in creative collaboration and product development, maintenance and remote repairs, designing and optimizing production operations, and workforce training

“The metaverse could become a game changer for industrial companies once they couple its collaborative, immersive, visual and intuitive dimensions with digital twins fed by integrated data pools across departments, systems, operations technology and IT,” Erhardt said. “This could create a virtual, fully immersive and intuitive simulation of the entire enterprise.”

Safety first

Companies are looking for ways to cut down on more menial tasks in factories with digital technology, amid a wave of labor shortages.

“Previously, automation has not been an option for manufacturing products due to minimal financial resources and investment,” Olivier Ribet, Executive Vice President, EMEAR at Dassault Systèmes, told CNBC.

“However, this is changing rapidly due to technological changes that have decreased costs and democratized automation through low/no code robotics allowing more manufacturing companies to leverage the advantages of automation in terms of precision, efficiency, and productivity.”

There are downsides to consider — not least of which job security — as the rise of AI and digital automation in factories has led to worries about the labor market. Generative AI, a relatively recent development, could erase 300 million jobs, Goldman Sachs estimates.

Still, history shows that technological progress doesn’t just make jobs redundant, it also creates new roles— which typically outpaces the number of jobs displaced. Manufacturers are still scrambling for staff, with 41% of manufacturing businesses citing talent pool as a “very significant” barrier preventing full potential, according to a Bain and Company survey.

The hope is that connecting machines to the internet and integrating sensors and predictive AI algorithms will allow them to more safely navigate their surroundings and work collaboratively with humans, rather than replace them, according to Maya Pindeus, CEO of AI startup Humanising Autonomy.

“Think of the factory, you have robot arms, you have different vehicles to move goods around, you have operators, you have safety cameras,” Pindeus told CNBC.

“What I would look at in the factory of the future is you have high levels of safe automation that can operate around people … I’ve been to factories where you have the big robot arm caged up and it’s really far away from people. It looks very inefficient to me.”

[ad_2]